Project Description

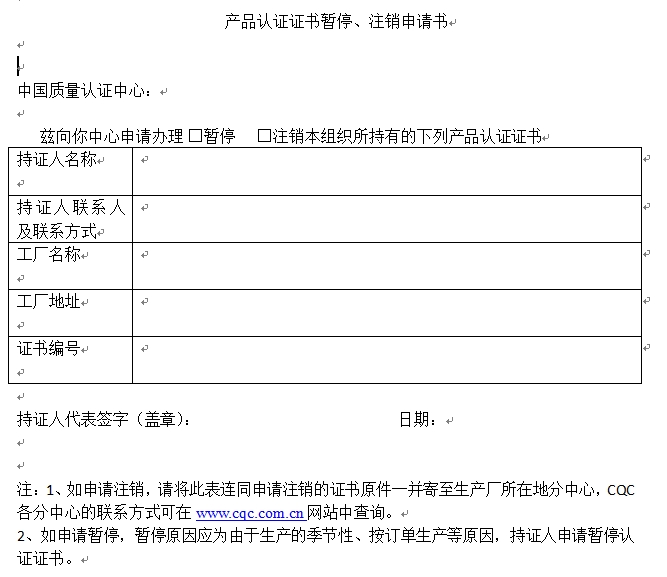

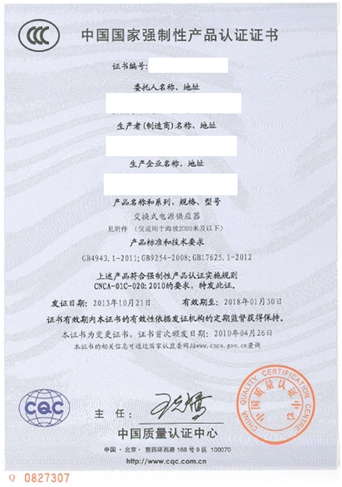

I. 3C certification nameplate or body application mark & certificate template::

1)3C mandatory certification unified mark

2)3C certificate Chinese and English certificate template

II. 3C certification introduction:

- 3C certification is a compulsory product certification introduced by China for the protection of national personal and property safety for some products that are exposed to dangerous products (the most common is the risk of electric shock, so most of them need to do 3C certification are charged products). system.

This is also an internationally accepted practice, such as the European Union has CE certification, Japan has PSE certification, Taiwan’s BSMI certification, etc., are mandatory product certification systems introduced to protect the safety of their nationals.

The reason why it is referred to as 3C certification, please see the following picture:

The three Cs represent three English words: China (China), Compulsory (mandatory) and Certification (certification), which together means: “China compulsory certification” means.

- 3C product certification scope:

01 wire and cable

02 circuit switch and electrical equipment for protection or connection

03 low voltage electrical appliances

04 low power motor

05 power tools

06 welding machine

07 household and similar equipment

08 audio and video equipment

09 information technology equipment

10 lighting equipment

11 motor vehicles and safety accessories

12 motor vehicle tires

13 safety glass

16 telecommunication terminal equipment

19 security technology prevention products

21 decoration products

22 toys - 3C certification conditions:

1) You must apply for 3C certification with your business license. Natural persons cannot apply for 3C with their ID card. Moreover, the business scope of the business license must include products that require 3C certification. For example, there are manufacturers to do 3C certification of toys, and there must be toys in the business license. Also in the name of the production companyIn order to apply for 3C certification, the business license must have similar words for production, manufacturing, and processing.

2) The factory must have basic production conditions. The so-called basic production conditions refer to the fact that factories can assemble or produce products according to their own production conditions, which is the most basic requirement for production.

3) Although there is no hardware requirement for the 3C certification, the requirements for the software are very high. For details, please refer to the “3C Certification Factory Quality Assurance Ability Requirements”. The factory needs to have a set of product quality assurance system documents to meet the 3C conditions, and fully implement Implementation, to ensure the stability of the quality of all manufactured products, especially to ensure large goods and

Consistency between samples for 3C testing. This is also the core condition of the factory inspection. For details, please refer to the Contents and Requirements of 3C Factory Inspection. In this regard, most factories, especially new ones, will seek the help of consulting companies to establish a product quality assurance system that meets the requirements of 3C certification. Group is the most specialized in China

The 3C certification consulting company can provide a full set of 3C audit quality system consulting services. If you have any needs in this regard, you can contact us.

4) The products to be inspected must pass the test of the corresponding national standard. This is the most important step in 3C certification. The company needs to prepare samples according to the requirements of 3C laboratories, send them to the laboratory for testing and pass the test.

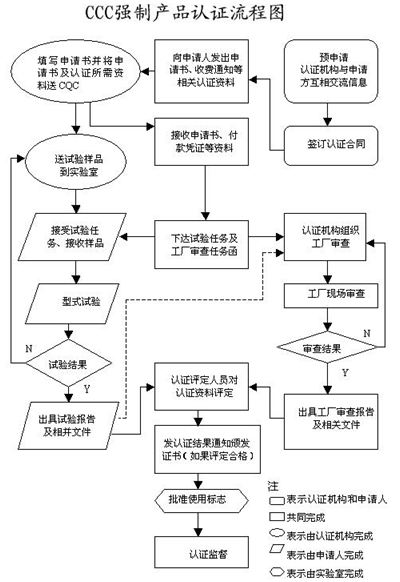

- 3C certification process:

The 3C certification process for most products is: certification application – “type test -” initial factory inspection – “certification results evaluation and approval -” after the certification.Frequency of post-certification supervision (annual review): Generally, it is once a year, and the toy category is once every six months.

However, at present, CQC (China Quality Certification Center) products are classified into factories that apply for 3C certification:

1. A/B level factory, when applying for 3C certification for the first time, can apply for a first-time certificate, and complete the initial factory inspection and factory inspection within 3 months from the date of issuance to ensure the validity of the 3C certificate.

2. For the C/D level factory, when applying for the 3C certification for the first time, the initial factory inspection must be carried out after the type test is completed, and the factory inspection is carried out before the approval of the 3C certificate can be obtained.

Remarks:

1. Some factories know the level of their own factories. Some factories do not know the level of their own factories. The name of the factory can be provided. CQC accepts engineers to assist in the inquiry and confirmation;2. If you have applied for 3C for the first time without applying for 3C certification, you can apply for the first pass and check the factory.

3. Flowchart:

- 3C certified factory inspection

Factory quality assurance capability + product consistency check1. The factory quality assurance capability review, first of all, it is necessary to make clear that the 3C factory inspection is carried out in accordance with the requirements of the Factory Quality Assurance Ability Requirements. For details, please refer to “Factory Quality Assurance Ability Requirements”

2. Product consistency check, consistency check on products that apply for certification, focus on verifying the following:

(1) The identity of the certified product (nameplate) and the consistency indicated by the type test report;

(2) The structure of the certified product and the consistency of the type test sample;

(3) The consistency of the important parts/components in the important parts/components of the certified product and the type test report;

(4) Conduct on-site inspections in accordance with the “Regular Inspection Items and Confirmation Inspection Items Table”.

It is necessary to emphasize that the product consistency check is the biggest focus of the 3C factory inspection. It is a “high-voltage line”. If there is a problem with the product consistency check, it will often lead to the failure of the factory.

3.3C factory inspection method:

(1) The initial factory inspection of 3C may be carried out separately or in combination with supervision and inspection;

(2) The initial factory inspection of 3C is generally one day for two auditors. The supervision and inspection is generally carried out by two auditors for half a day. Of course, sometimes it is necessary to review the day and see the specific situation.

(3) Since the factory inspection includes document inspection, it also includes on-site inspection. There are divisions between the two auditors, one is biased towards document inspection and the other is biased towards on-site inspection.

- 3C certificate change:

1) The following changes can be applied for changes: 1. Trademark changes2. Names and model changes of certified products due to changes in product naming methods

3, the product model changes, does not affect the internal structure of electrical safety remains unchanged (after judgment does not involve safety and electromagnetic compatibility issues)

4. Add other models of the same product to the certificate.

5, reduce other models of the same product on the certificate

6. The name of the production enterprise is changed, the address is unchanged, and the production enterprise has not been relocated.

7. The name of the production company is changed, the name of the address is changed, and the production company has not been relocated.

8. The name of the production enterprise is unchanged, the address name is changed, and the production enterprise has not been relocated.

9. Relocation of production enterprises

10. Change of name and/or address of the original certification client

11. Change of name and/or address of the original producer (manufacturer)

12. The national standards, technical rules or certification implementation rules on which the product certification is based have changed.

13. Significantly affected product design and specifications have changed, such as changes in electrical safety structure or replacement of key parts of certified products

14. Increase/decrease the change of the name of the key component supplier or key component supplier with consistent applicability

15. The quality system of the production company has changed (for example, ownership, organization or manager has changed)

16. Other institutions apply for renewal

17. Expiration renewal

18, other

2)Application for suspension or cancellation of product certification certificate